The Schuko brand stands not only for innovative and powerful solutions, but also for high economic efficiency, durability and optimal safety both in the workplace and for the environment. As a family-run enterprise, we are built on our close relationships with customers.

Our colleagues live up to this claim every day with know-how, experience and comprehensive service. The satisfaction of our customers from industry and the trades proves that we are on track for continued growth in the future – in our core market of Europe and beyond.

Schuko Products & Systems

Extraction, surface and filtration equipment

Mobile Dust Extraction

Mobile, space-saving and powerful

Mobile extraction units are equipped with casters for indoor installation to provide for clean, dust-free air right at the workstation. They are perfect for extracting dust and chip waste in workshops and industrial operations. Whether for dust extraction from the machine or for direct chip extraction from the workshop floor, thanks to their mobility they can be set up and connected flexibly at any location.

Our mobile extraction systems are ‘made by Schuko’ to the latest state of the art. They provide high extraction performance at a low power consumption and boast impressively high quality, long life and cost-effectiveness.

Filter Systems

Powerful extraction centres in the modular manner

Central extraction systems detect production waste, such as dust and chips, via pneumatic conveying directly at their respective place of origin. The dust-laden air produced during grinding, milling, planing, welding, cutting or similar manufacturing processes is extracted and cleaned in a centrally installed filtration system.

Schuko filtration systems are designed to order and manufactured to customer specifications. Our extraction and filtration technology contributes significantly to product quality and occupational safety in numerous industries. The required safety requirements (explosion protection, pressure shock resistance, dust limits) are of course respected for the protection of the employees and the environment

Sanding Tables

Sanding tables for wood or lacquer sanding

Type Octopus and SAT sanding tables suck the resulting dusts directly from the entire table surface. The result is a low-dust and clean sanding workstation, which allows its user easy operation with many details. Octopus extraction tables do not have their own drive and are therefore suitable for connection to an existing extraction system.

SAT grinding tables, on the other hand, are equipped with their own drive and a filter function and can be installed in the workroom independently of any additional extraction.

With these grinding tables, it is possible in practice to optimally solve the problem of dust from an economic point of view.

Shredders

For residual wood shredding

Wood shredding system that offer a seamless solution for effortlessly processing a variety of materials, including waste wood, residual wood, MDF, chipboard, and pallets. With the flexibility of different screen sizes, you can achieve the desired final chip dimensions tailored to your specific requirements. Additionally, these system allows for chip briquetting, adding versatility to the waste management process.

Boasting a high throughput at a low noise level, the energy-saving design features the latest IE3 motors, ensuring efficiency in operation. Incorporated is an automatic idle machine shutdown for enhanced safety and energy conservation. With long-lasting, replaceable blades and a robust, durable construction, these wood shredding system are engineered to deliver reliable performance over an extended lifespan.

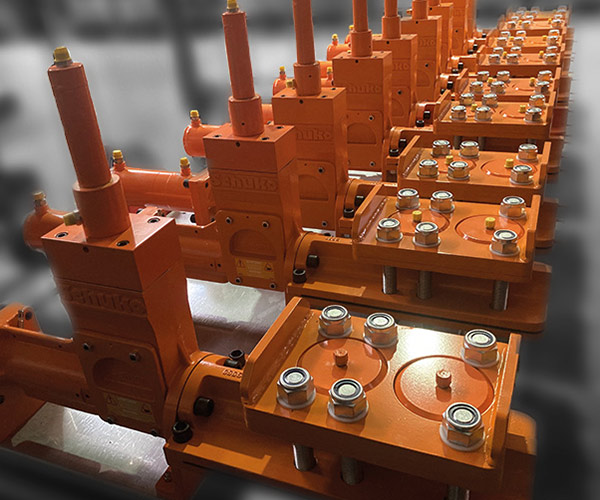

Briquetting Presses

Compacto briquetting presses

Hydraulic briquetting system is designed to efficiently process a diverse range of cutting waste materials. This includes sawdust, wood shavings, and wood chips, providing an effective solution for wood-based waste. Moreover, the system accommodates plastic chips such as styrene, polystyrene foam, PU, and PVC, along with shredded paper and paper dust.

For sustainable practices, biomass materials like Miscanthus and hemp can be easily processed. The system also handles nonferrous metal swarf, including copper, aluminum, zinc, bronze, and brass, contributing to metal recycling efforts. Shredded recycled materials, tobacco dust, and even jeans dust find effective utilization through our hydraulic briquetting technology, showcasing its versatility and eco-friendly capabilities

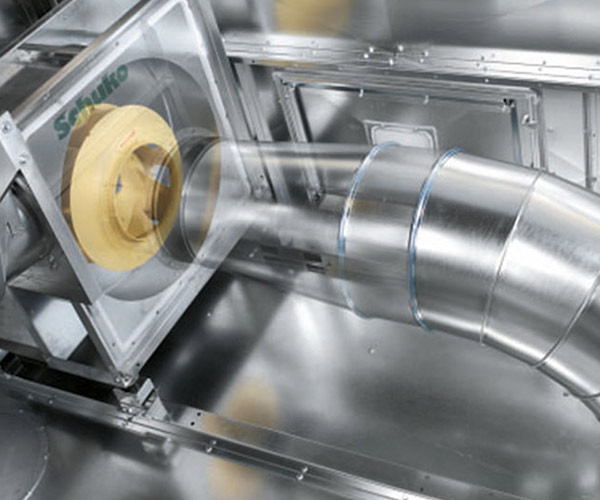

Industrial Fans

The heart of an extraction system

Welded industrial radial fans, meticulously engineered for optimal performance, are an ideal choice for various applications. Their design is particularly well-suited for the pneumatic conveyance of dust and chips, showcasing versatility in handling challenging materials. The pressure-tight welded housing enhances adaptability, allowing for use with extraction systems on both the dirty air or purified air side.

An option for a noise-reduced version caters to those seeking a quieter operation without compromising efficiency. These fans feature highly effective impellers, developed and produced in-house, ensuring top-tier quality and performance. Crafted in Germany with German motors, these radial fans embody precision engineering and reliability, meeting the esteemed standards associated with German craftsmanship.